Shifting the tank into position

by

, 11-20-2010 at 09:01 PM (5852 Views)

As you know, the Marineland 400g is pretty heavy. It took 8 of us to lift it into position and place it on the stand. It took four of us to carry the stand in. Combined, it's probably 1600 lbs. I'm home alone, and I want to shift it into position, aligned with the walls of the house.

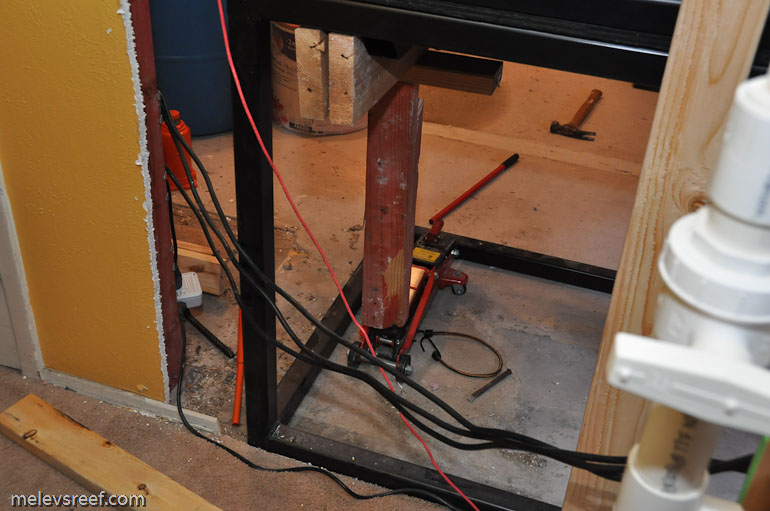

Being an only child, the one thing I've always been good at is coming up with a way to do it myself and not wait until someone can come over. I appreciate the help, but I hate waiting if there's an option at my disposal. Using a 2-ton roll-away car jack, a 38" header, and a 22-ton can jack, I figured this can't be that big of a deal.

The tank was hoisted up on the 2-ton jack, using the header to lift the tank and stand at once. The can jack was placed against a solid object and with a little leverage the tank could be moved over an inch.

Then it had to move toward the kitchen about half an inch.

Using an 8' 2x4, I checked and rechecked that the sheetrock at the ceiling was in line with the plastic trim of the tank and the metal leg of the stand.

The overflow end of the tank had to come into the fishroom about 1/4" to keep the plastic trim flush with the sheetrock in the hallway.

It is where it belongs.

Now it is time to level it, and I'm open to suggestions. The concrete is uneven and looking at the tank from the kitchen end (the Starphire panel), the right corner needs to come up 1/2". Once it is up where it belongs, the far end (the overflow) will have to come up as well.

The slab concrete can hold the weight, and the stand is powdercoated. I'm trying to decide what to put under the corners of the stand that will hold up long term, can handle getting wet from time to time, and not do damage to the steel frame (rust or electrolysis). I'm thinking the material needs to be 2" wide like the tubing, and probably extend about 6" from the corner to help spread out the weight over a bigger area. Bobby suggested flat stock, like aluminum or stainless steel. I know that oak shims are used to level homes, but they don't get soaked in saltwater when accidents happen.

Since the tank is in place, I don't intend to pour some type of concrete mix to fill such a void, but I'm wondering if slopping some type of mastic or similar material to fill in the gaps might be worth doing.