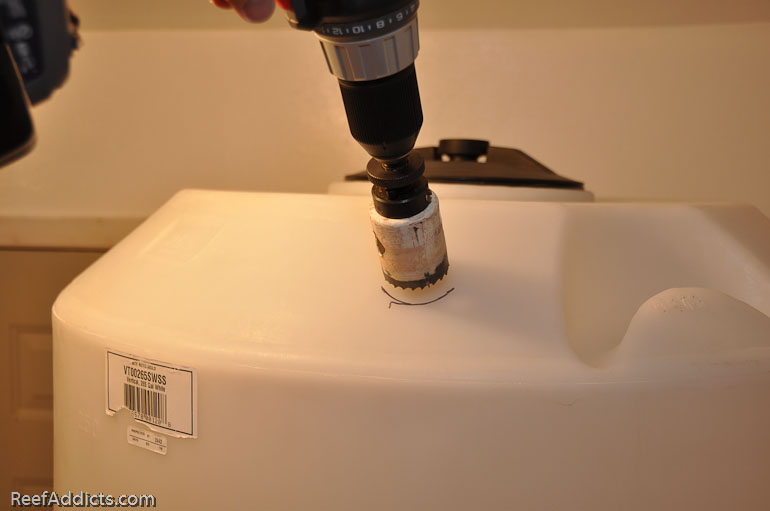

A 1 3/8" hole saw is the right size for a 1" uniseal.

To avoid shavings inside the poly tank, I held a bowl in place inside under the surface about to be drilled. The hole was cut in less than 20 seconds.

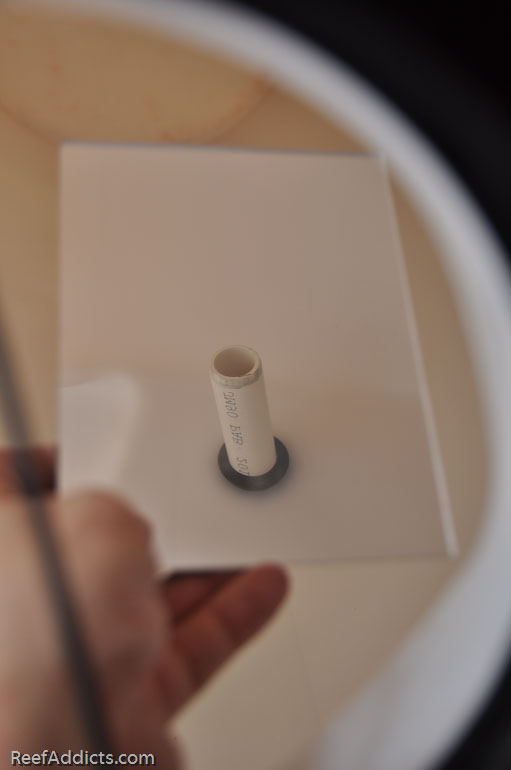

A 9" piece of PVC pipe was cut, which has to be pressed through the uniseal. To make this job easier, the first thing I did was taper the end with a dremel tool.

This makes people laugh, so I can't leave out this little tip: Astroglide is the easiest way to get PVC into a uniseal. Trust me. hehe

From inside the poly tank, using a small mirror, you can see the pipe installed

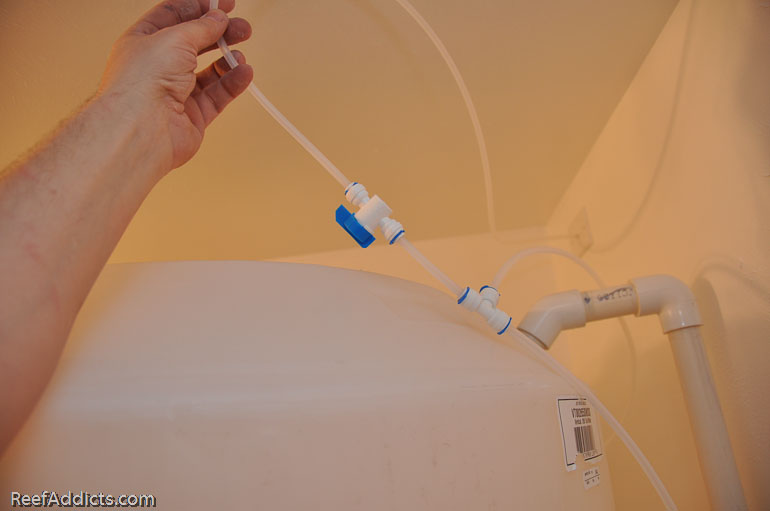

While the poly tank was being drilled, I wanted to get a float valve installed as well. RO/DI water will fill up the tank until the float valve rises and pinches off the line (in theory), shutting off the RO/DI system. I'll have a 1/4" ball valve inline to shut off the water going to the poly tank to avoid accidents. Once a month I'll open the valve to collect more RO/DI water for the next batch of saltwater.

This one is a little different than most floats.

Open, water flowing:

Closed, water stopped:

The wall of the poly tank is almost too thick for this particular float, but it worked out. 1/4" icemaker/RO tubing fits into that tiny opening.

Here's a picture inside to the poly tank using a mirror to see the float valve.

Back to the return pump vertical pipe, it's time for the last few pieces. Dry fitting again helped determine how tall the vertical pipe needed be.

Measuring the distance between the poly tank and the vertical plumbing nearest the pump, I tried to match that distance near the top. The pipe is 3.5" from the poly tank. Keeping that distance, this horizontal piece was cut to fit.

Primer & cement, press together and hold, then wipe the excess glue away and this is how it looked.

The last step is to add the horizontal feed to the sump area. Very easy, using the last of the PVC pipe and the second double union ball valve (DUBV)

The entire tank was pushed into place up against the wall.

Time to hook up the RO/DI system to it! Because it takes so long to make water and it was at least a couple of hours since I glued the first few fittings together, I didn't have to wait. Here's where the tubing comes into the fishroom.

Here's the cut-off valve to stop water from feeding into the fishroom, then into a Tee fitting, which feeds the 265g reservoir and the other line will be for the automatic top off reservoir (not pictured at this time).

The water is coming from the 150gpd Boosted RO/DI system in my utility room, which is about 25' from the poly tank.

Look closely and you'll see the water droplets.

Filling it up at last.

At the time of this writing, it has been 22 hours and over 105g are collected. Once the vat is full, salt will be added and the circulation pump will be plugged in to mix it up and get it aged.

I hope this article has helped you understand the basics of plumbing using this real life example. The next article will feature how to plumb a reef tank correctly, and it will be just as thorough.

Menu

Menu

Reef Addicts Message