**This article is multi-page format, meaning you will have to click to the next page in the drop down menu available at the top and bottom of each page. **

General rules of thumb:

- You can make mistakes - it's okay. Redoing a section is as simple as replacing a few fittings.

- It's cheaper than hiring a plumber - well, generally speaking. The fittings are going to add up quickly, shockingly so. And if you flood the area, that can be expensive to repair.

- Common household tools are all you need - yes, this is true. Nicer tools provide better overall results.

- Always use primer & cement. No matter what you are told, this is indisputable to avoid leaks.

- It is safe to use with your reef - yes, with this stipulation: fresh glue has toxins, but once cured for a few hours and rinsed clean it is completely safe. If you have to glue in a section in an emergency, glue all you can away from the tank, let it set up, rinse it under water (garden hose or in the tub) and then glue only the last one or two fittings inline. Reducing the total amount of fresh glue in your total water volume is the goal.

- Not all fittings are made the same. Some fittings are slightly oval instead of round; some unions won't match others that look the same because of variants during different production runs; some components are just a bad choice period and often you'll be told about some evil part after you've installed it.

- No metal is allowed in a saltwater set up, ever. No copper, no brass, no lead - all plastic parts all the time.

- Sharpie

- Box cutter

- PVC cutter

- teflon tape

- teflon paste

- PVC primer and cement

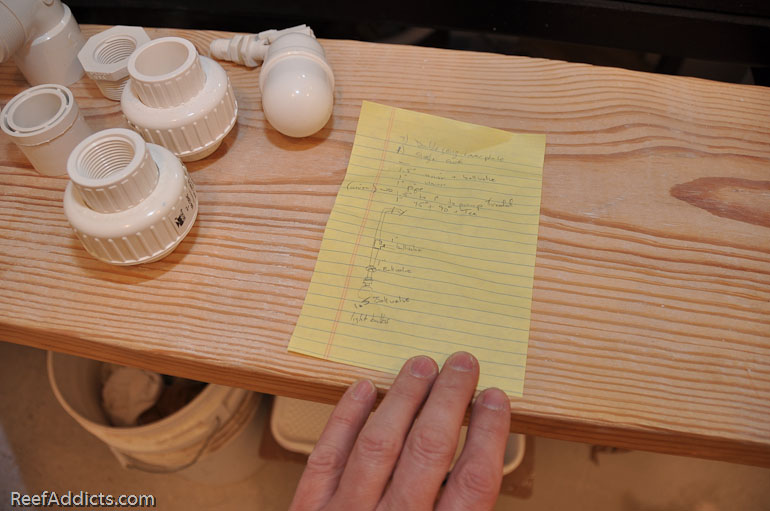

The next thing you need is a general sketch of the idea. Do this before you head to the store, and think about what you need for the entire project. Write a shopping list. Then as you buy the parts, lay them out like a jigsaw puzzle in your shopping cart to visualize what you're getting and what's been forgotten or omitted.

Once you get home, you'll have something that looks like this...

...and at least one of these, the cheapest part of the entire project. This is a 10' section of 1" Schedule 40 PVC pipe. Industry standard, comes in sizes 1/2" to 3" at any hardware store.

Here are some plumbing basics, fitting by fitting. Everything is 1" unless otherwise stated.

PVC Elbow

This is a 90 degree elbow fitting. Both openings are smooth inside, so it is called a slip/slip fitting. It is also sold with one or both openings threaded internally.

This is a threaded/slip elbow, which would only be used for specific applications like this one. It is 1.5" x 1.5"

PVC 45

This is a 45 degree fitting. Both openings are smooth inside (slip/slip). The benefit of this fitting is to soften a corner or to align plumbing that can't be joined with a 90 degree elbow.

PVC Adapter or Reducer

This fitting is designed to fit inside a larger piece of plumbing to create a smaller inside diameter. If the plumbing is 1.5" and needs to switch down to 1", use a reducer. Reducers can be slip/slip, slip/threaded, or even threaded/threaded.

Slip:

Threaded:

PVC Tee fitting

This fitting allows an extra line to be added to the main line. Tee fittings come in slip/slip/slip configuration, and the perpendicular opening can even come in a smaller size. For example a 1" Tee may have a 3/4" or 1/2" threaded opening, such as used for long runs underground that have a sprinkler pipe screwed in every 20' pointing upwards. When purchasing Tees, look at every one of the closely to avoid bringing home a mixture. Better yet, buy the bulk bag that has 10 identical ones, and return what you didn't need.

PVC Ball valve

The ball valve comes in various colors depending on application. White with red handles is pretty standard. The handle is hard to turn, and should be opened and closed periodically to prevent them from freezing into one position. It is used to close off a pipe when you need to work on the next section or to remove a pump without draining everything in the system first.

Ball valves come in all sizes, and are usually sold slip/slip or threaded/threaded.

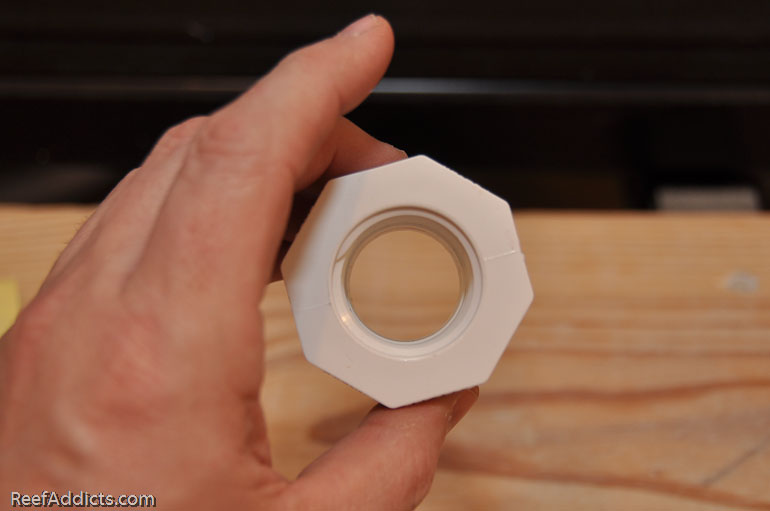

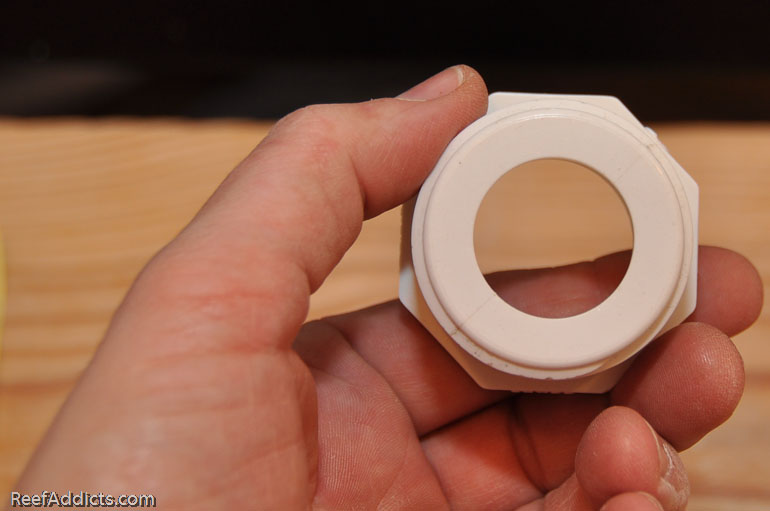

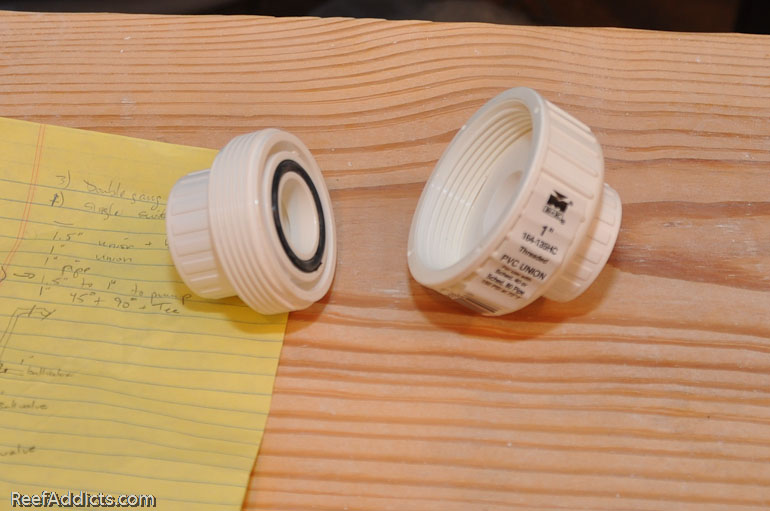

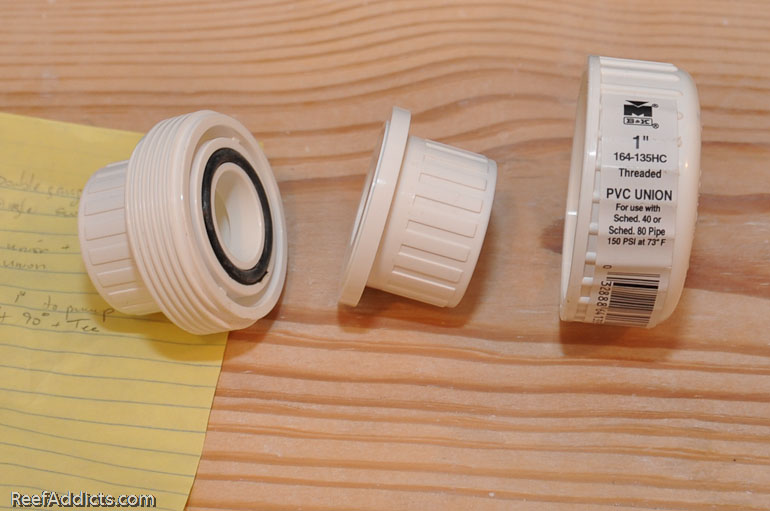

PVC Union

This fitting is one of my favorite choices when joining two sections of PVC together because I can take it apart later. The most likely place to use these is before and after an external return pump that needs to be removed from time to time for servicing. Unions can be used where plumbing needs to be removed temporarily, such as when you have to extract a skimmer from a tight spot under the tank and the drain line is in the way. Be sure when you purchase these that you open them up and make sure the black O-ring is included.

Double Union Ball Valve

This is the best of both with a union on each end and a ball valve in the center. These cost more, and usually have to be purchased online from Savko.com but are totally worth it. The handles are very easy to turn, and plumbing can be removed from either end.

Uniseals

The uniseal is a handy rubber grommet that goes in the side of a sump or water storage container. PVC is pressed through the uniseal creating a water-tight bond. Uniseals take up less space than a standard bulkhead. This too was needed specifically for this project, and had to be purchased online. (You may have noticed these on some protein skimmers.)

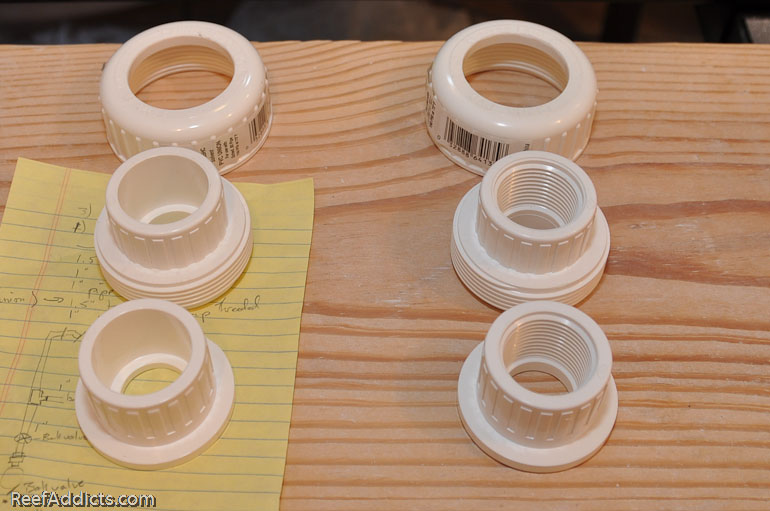

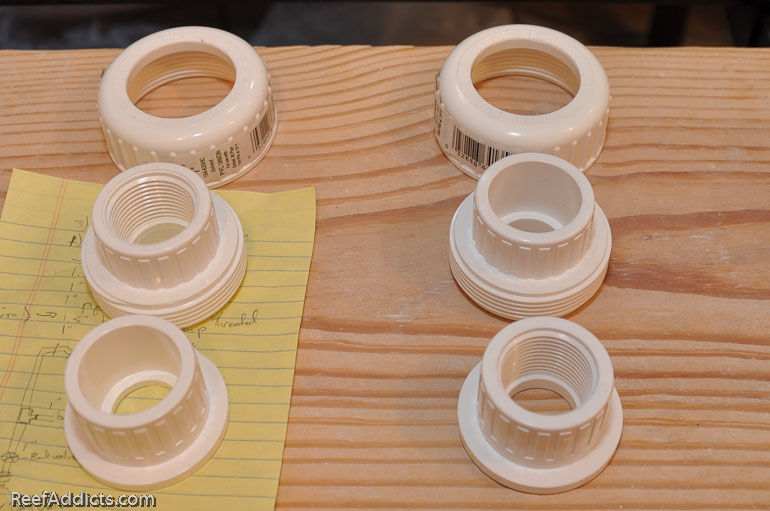

Mix and Match Unions

Sometimes you will want one side of the union to be slip with the opposite side threaded. I need the threaded side to screw onto the pump's inlet and outlet, and I need the plumbing to glue into the other half. Buy one of each, and swap out the parts to get the 50/50 (slip/threaded) combination.

Standard, slip on the left & threaded on the right.

Swapping the two middle pieces...

Done.

Now that you know what these parts are, it's time to tackle a project. I had to plumb an external pump to a 265-gallon poly tank that will store saltwater. Water needs to exit the base of the poly tank, flow through a pump that pushes it back up to the top and pours back down, mixing and circulating the saltwater so it's always ready.

Before doing anything else, lay out your project so you can see how it will progress.

A common question I get is what goes between the fittings. That would be a small piece of that 10' long PVC pipe you saw pictured above. No hardware store is going to sell you 2" and 3" long pieces of PVC, but you can purchase shorter sections that are 24" long. It's far more economical to buy the full stick of PVC and cut it down as needed.

- Every fitting has a specific depth the PVC can sink in, so measure the distance between the two fittings and include the socket depth of each fitting.

- During a dry test run, you will not be able to push the pipe fully into the socket. If you did, you won't be able to take it apart unless you've got brute strength. Press them together slightly to get an idea of what is supposed to happen, but remember during the gluing process they will sink in further - this can make your section become too short if you aren't thinking ahead. Take your time and measure carefully.

Menu

Menu

Reef Addicts Message