Upgrade to 340 G tank changed to 390 G tank.

by

, 05-03-2011 at 04:13 PM (2185 Views)

Finally after months of delay the build continues with some changes:

-Tank volume was upgraded to 390G for the display after a friends suggestion to increase the length 20 cm more.

-Final dimensions are 220x85x75 (88"x34"x30")

-Starphire on front and side panels.

-Minimalistic Scape

-External side overflow.

-Additional 1000L 265G in Sump fuges and additional sump and fuges in fishroom and connected water change tank so around 2400L 655 G total water volume.

Most other planned electrical, Plumbing and filtration plans remain as in the 340 G thread.

Glass:

Note the difference between the bottom and back glass and the rest of the pannels. the rest are much clearer than in the pictures but pick up some greenish tint when close to green glass.

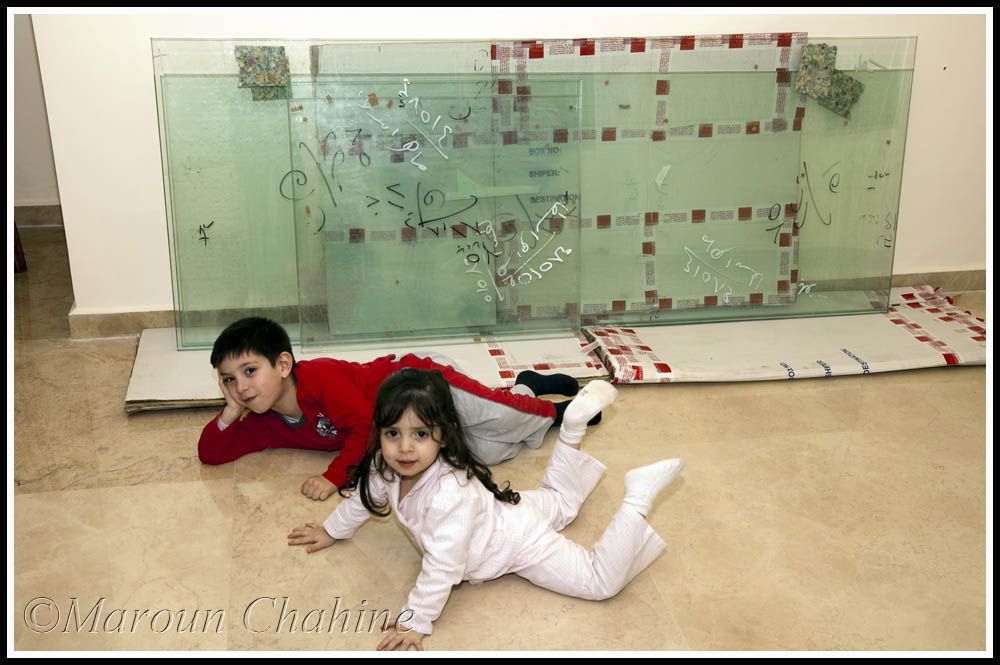

And my assistants rushing to pose in front of the glass any time I hold the camera.

Tank was assembled on site by Maher a very old friend who sets up and maintains some breathtaking tanks. His perfectionism and attention to detail were just amazing. My tank sure reflects this.

Wanted to shoot a thousand pics while he was assembling the tank but didn't want to stress him out:

Under the clsoe watch of the wife:

Back to the tank,

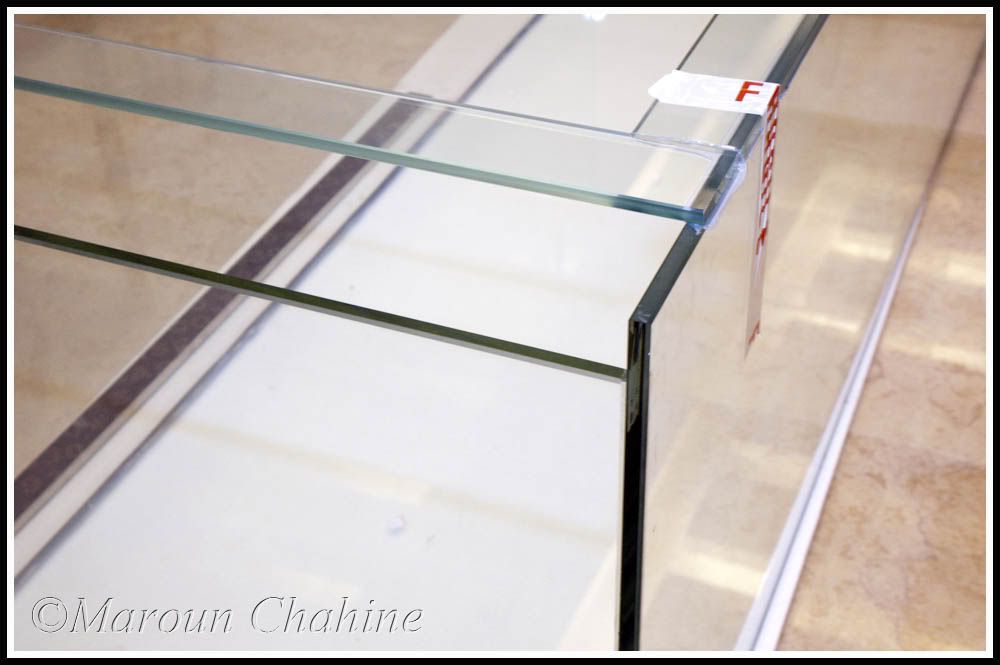

Some pics after the masking tape was taken off the seams, minutes after tank was assembled.

I can clearly see huge differencebetween back and front glass glass, much more than visible on pics between back wall and other panels. Canít wait to shoot some pics of corals in it.

Eurobracing installed. Space kept on the left side for easier manipulation of tubing coming out of overflow, as well to use the brace to support screen material to prevent fish from jumping in overflow.

Silicone that burst out from the seams was cleaned with a blade after it dried out for days and I could see for the first time how clean the seams turned out